ENEMAC. Antriebstechnik für Anspruchsvolle. Sicher seit 1981.

Drehmomentbegrenzung und Überlastschutz sind unser Metier. Insbesondere die Absicherung von direkten und indirekten Antrieben in anspruchsvollen Bereichen treibt uns an. Um den besonderen Hygieneanforderungen der Lebensmittel-, Pharma- und Medizintechnik gerecht zu werden, entwickelten unsere Konstrukteure Sicherheits- und Wellenkupplungen speziell für diese Anwendungen. Ob korrosionsgeschützt oder aus Edelstahl im Hygienic Design, trotzt unsere Antriebstechnik Wind & Wetter sowie Wasser & Säure. Ein breites Produktportfolio bietet für nahezu jedes Antriebsproblem die passende Lösung. Ob Standardanwendung oder Extremeinsatz - ENEMAC Maschinentechnik für alle Fälle, kontaktieren Sie uns gerne.

Produktkompass

Unser Produktkompass hilft Ihnen bequem, die passende Sicherheits- oder Wellenkupplung für Ihre Anwendung zu finden. Relevante Auswahlkriterien erleichtern die Produktsuche und ermöglichen eine konkrete Anfragestellung über diese Seite oder dienen als Vorauswahl für das persönliche Gespräch mit unserem Kundenservice.

ProduktkompassProdukte

Sicherheitskupplungen

Mechanischer Überlastschutz zur Minimierung kostspieliger Reparaturen und Maschinenstillstände

ENEMAC Sicherheitskupplungen minimieren durch ausgereifte Drehmomentbegrenzung (Überlastschutz) zuverlässig kostspielige Reparaturen und Maschinenstillstände. Innerhalb kürzester Zeit wird im Störfall der Antriebsstrang mechanisch unterbrochen und destruktive Massenkräfte und Drehmomentspitzen werden sicher weggeschaltet. Spielfreie, exakte Drehmomentübertragung, stufenlos einstellbare Ausrückmomente und automatisches Wiedereinrücken sind charakteristisch für ENEMAC Sicherheitskupplungen. Ihre Einsatzmöglichkeiten erstrecken sich über den gesamten Maschinen- und Anlagenbau, sowohl für direkte als auch indirekte Antriebe.

Wellenkupplungen

Ausgleichkupplungen zur exakten und spielfreien Drehmomentübertragung von Antriebs- auf Abtriebswelle

ENEMAC Wellenkupplungen sind Ausgleichskupplungen zur spielfreien, winkelgetreuen Übertragung von Drehmomenten von 0,4 Nm bis 65.000 Nm. Sie können typenabhängig bei Drehzahlen bis zu 57.000 min-1 und Betriebstemperaturen von bis zu 350°C eingesetzt werden. So vielfältig die Anwendungsmöglichkeiten von Wellenkupplungen sind, so breit gefächert ist das Produktportfolio von ENEMAC. Es reicht von Metallbalgkupplungen über Elastomerkupplungen bis hin zu Lamellenkupplungen.

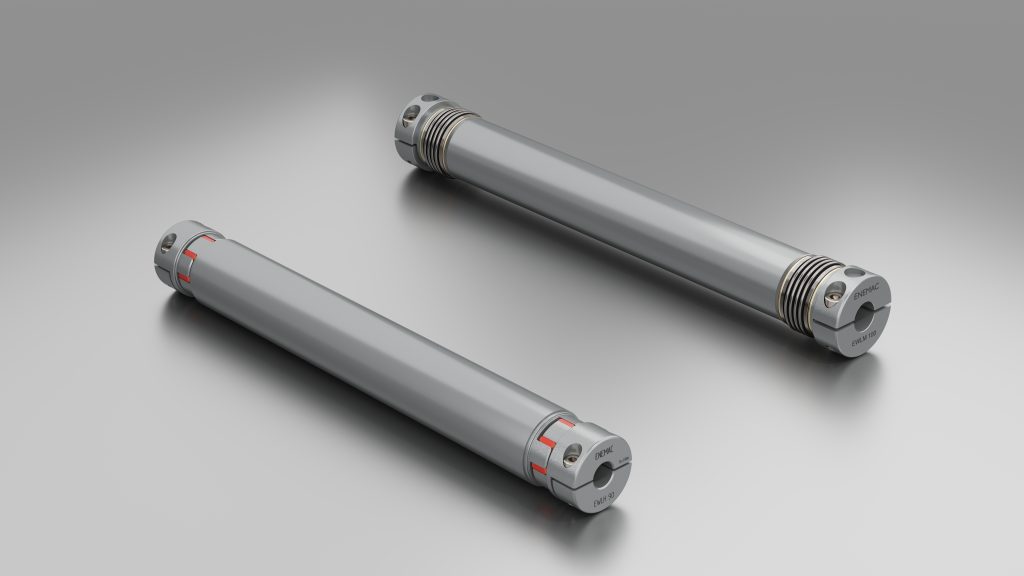

Distanzkupplungen

Ausgleichskupplungen zur Überbrückung großer Achsabstände

ENEMAC Distanzkupplungen sind Wellenkupplungen zur Überbrückung großer Achsabstände und zum Ausgleich von Wellenversatz. Durch längenvariable Zwischenrohre aus hochfestem Aluminium, welche nach Kundenwunsch angepasst werden, können Distanzen von bis zu 6 m überwunden werden. ENEMAC-Distanzkupplungen können als spielfreie Verbindungs-, Gelenk- oder Synchronwellen bei Temperaturen bis zu 300 °C eingesetzt werden und decken einen Drehmomentbereich von 10 Nm – 1.600 Nm ab.

Edelstahlkupplungen

Sicherheits- und Wellenkupplungen aus Edelstahl im Hygienic Design

ENEMAC Edelstahlkupplungen entsprechen den strengen Hygienevorschriften der Lebensmittel- und Pharmaindustrie und können ebenfalls im Bereich der Medizintechnik und in Reinräumen eingesetzt werden. Bei der Herstellung von Sicherheits-, Wellen- und Distanzkupplungen im Hygienic Design werden Edelstähle A2 und A4 verwendet und somit höchste Qualität für anspruchsvolle Einsätze gewährleistet.

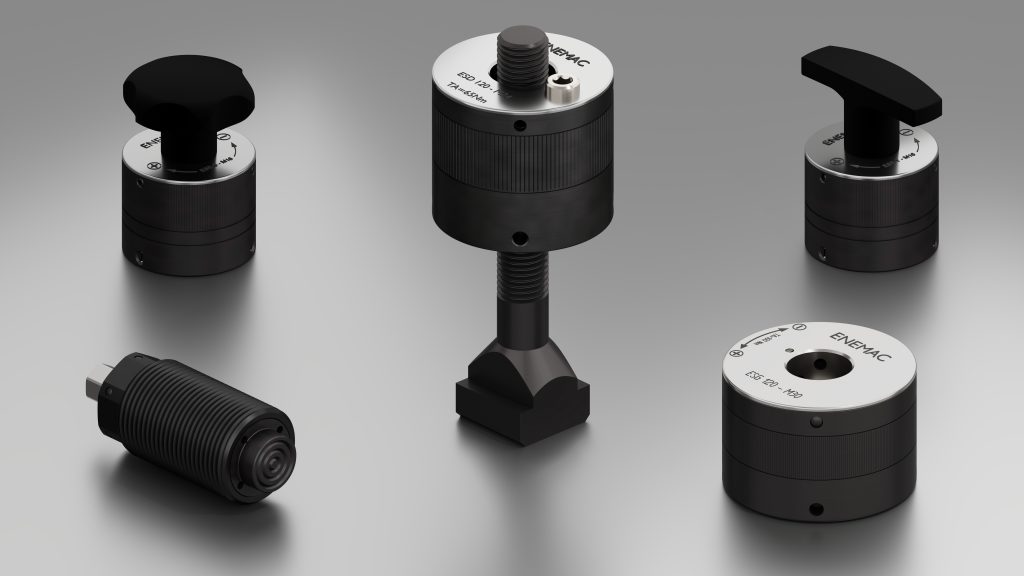

Spanntechnik

Kraftverstärktes Spannen von Werkzeug und Werkstück

ENEMAC Spanntechnik garantiert sicheres und kraftverstärktes Spannen von Werkzeugen und Werkstücken mit einer Nennspannkraft von bis zu 350 kN. Mit verschiedenen Kraftverstärkersystemen und hydromechanischen Federspannsystemen steigert ENEMAC Spanntechnik sowohl Betriebssicherheit als auch Wirtschaftlichkeit in Ihrer Produktion und verkürzt zudem Rüst- und Fertigungszeiten. ENEMAC Spannelemente können als Erstausrüstung in Maschinen oder nachträglichem Retrofit eingesetzt werden.

Kontaktformular

Unsere Kunden

So vielfältig wie unsere Produkte sind auch deren Anwendungen. Eine Auswahl unserer Kunden und damit einen Einblick in die zahlreichen Einsatzmöglichkeiten möchten wir Ihnen hier vorstellen:

Als international tätiger Hersteller von Abfüll- und Verpackungsanlagen für die Getränke-, Food- und Non-Food-Industrie nimmt die KHS GmbH eine führende Stellung in der Branche ein. An fünf deutschen Standorten sowie weiteren Produktionsstätten in Brasilien, den USA, Mexiko und Indien entwickelt und fertigt KHS das gesamte Portfolio an Abfüll- und Verpackungsmaschinen. Im Sinne ihrer Unternehmensverantwortung legt die KHS GmbH besonderen Fokus auf die Entwicklung von nachhaltigen Lösungen, eine umweltschonende Produktion und soziale Aspekte.

IWK Verpackungstechnik GmbH richtet ihren Fokus auf die effiziente, präzise und attraktive Verpackung von Gütern aus den Bereichen Pharma und Kosmetik. Gute Ideen in Kombination mit dem Pioniergeist des Unternehmens haben IWK zu einer starken, weltweiten Präsenz verholfen. IWK besitzt momentan eine beträchtliche Zahl von Patenten für Schlüsseltechnologien und investiert jedes Jahr deutlich mehr in Forschung und Entwicklung als der Branchendurchschnitt. Daraus resultieren jährlich zahlreiche Innovationen. IWK verfügt über 2 Produktionsstätten in Europa und Asien und beschäftigt heute rund 450 Mitarbeiter, die meisten davon am Hauptsitz in Stutensee, Baden-Württemberg.

KOLBUS bietet das weltweit umfassendste Produktprogramm für Buchbindereimaschinen. Es setzt sich aus über 30 Maschinentypen zusammen, die sämtliche Anwendungsbereiche zur Fertigung gebundener Produkte ab dem gefalzten Bogen abdecken (u. a. Zusammentragen, Klebebinden, Trennen und Dreischneiden, Buchdeckenfertigung und -veredelung, Buchendfertigung, Anlegen, Stapeln und Transportieren). Inlinefertigungsanlagen für die Produktion von Zeitschriften, Katalogen, Paperbacks und Hardcover-Büchern sind eine KOLBUS Spezialität. Rund um den Globus ermöglichen KOLBUS Produktionsanlagen täglich Erträge und neue Chancen in den verschiedenen Produktsegmenten – begleitet von Verlässlichkeit und konsequenter Qualitätsorientierung.

Die NIKO Nahrungsmittel-Maschinen GmbH & Co. KG wurde 1976 gegründet und hat sich seitdem als verlässlicher Spezialist für Maschinen und Anlagen für die Lebensmittel- und Getränkeindustrie weiterentwickelt. Die Konstruktion der Maschinen und Anlagen basiert auf den aktuellen, gültigen Maschinenrichtlinien und orientiert sich an den Prinzipien und Forderungen der Nahrungsmittelindustrie (IFS, HACCP, ISO- und CE-Zertifizierung). Unsere Anlagen zeichnen sich durch eine hohe Produktionseffizienz, einfache Reinigung und Wartung und niedrige Instandhaltungskosten aus. NIKO realisiert Maschinen für folgende Industrien: Konservenindustrie, Feinkostindustrie, Getränkeindustrie, Süßwarenindustrie und Snackindustrie.